What is Ground Penetrating Radar (GPR) and how does it compare to concrete x-ray ?

Concrete x-ray uses ionizing radiation, which is hazardous and can cause serious health problems which may not develop for many years. Hence, when concrete x-ray is used, extensive safety procedures and exclusion zones are required, which makes concrete xray difficult in most situations. Concrete x-ray also requires access from both sides of the slab, which may not always be possible.

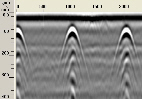

GPR transmits pulsed high frequency radio waves into the concrete which then reflects back to the receiver. The receiver is located within the same antenna unit as the transmitter. This means investigations can occur from one side of the slab and there is no need for exclusion zones.

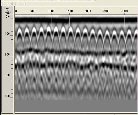

GPR is ideal for location of post tension-cables (PT),

reinforcement, service location and conduits making it safer to

drill, cut or core concrete. This scan was performed on a ground slab, which would not be possible with concrete x-ray as there is no access to the reverse side. The scan shows three PT cables which were easily avoided during cutting.

As GPR can be performed form one surface it is also ideal for

under bridge scanning on pile caps, headstocks, girders, deck units etc.

Concrete xray would be quite difficult accessing both surfaces.

The image on the right shows the steel placement within the pile cap.

GPR can also be used for concrete slab thickness and void location.

GPR in conjunction with electromagnetic field detection

can assist in locating and tracking high voltage electrical cables

within the concrete slab.

The image on the right shows several,

live high voltage cables, entering the concrete slab. These can be

traced using a high quality electromagnetic field detection unit.